| |

| ENVIRONMENT PERFORMANCE |

| WATER |

|

|

| Water Conservation Initiatives |

|

| |

Water Conservation

at API Manufacturing

Unit-5 |

| Reduction of fresh water usage ranks high on our sustainability list and an alert was raised when the groundwater utilisation of API Manufacturing Unit-5 touched a high of 1,290 kl per day in FY12. We rolled up our sleeves and undertook a target to reduce the fresh water consumption by 50% i.e. 650 kld by FY15. |

| Extensive studies were conducted and multiple options evaluated. Among them were retrofitting the existing system, use of innovative technologies like electro coagulation, a high efficiency RO system and harvesting storm water. |

| The following areas were identified as potential sources for fresh water conservation. |

|

| |

| Focus Areas |

|

Proposed Solution |

|

Expected Reduction

in Fresh Water Usage |

| Boiler feed water |

|

Treat the RO permeate and make it suitable for use as boiler feed makeup water |

|

450 kld |

| Steam condensate |

|

Segregate the steam condensate from the major steam consumers and reuse for cooling tower makeup |

|

65 kld |

Domestic wastewater

treatment |

|

Treat the domestic wastewater in an STP and reuse for gardening |

|

40 kld |

| Storm water |

|

Collect and treat storm water and increase the efficiency of existing membrane filtration systems |

|

70 kld |

|

| |

The potential was translated into outcomes by investing talent,

capital and requisite infrastructure. |

| Treatment of Wastewater to meet Boiler Feed Water Specifications |

| For the consistent performance of the wastewater recycling plant, it was essential to maintain consistency in influent parameters like TDS, BOD, COD, turbidity, hardness etc. |

| Wastewater pre-treatment was strengthened by replacing the coarse bubble aeration with Trion process mixers in neutralisation and equalisation tanks, providing dosing systems and mixing agitators. |

|

|

| Fresh water usage reduction by |

| 450 kl per day |

|

|

| |

| Steam Condensate Segregation and Reuse |

|

The Thermo Vapor Re-compressor (TVR) was removed from the existing MEE-1, and

an equivalent HT body was added to recover the steam condensate. This resulted in

saving 15 kld of freshwater. |

| A 200-kld MEE without TVR was installed to process Sodium Sulphate effluent. The steam condensate was recovered, and we could conserve 50 kld of fresh water. |

|

|

Fresh water usage

reduction by |

| 65 kl per day |

|

|

| |

| Fresh Water Conservation by Recovering Water from |

|

New utility RO system: A fully automatic PLC-based 3-stage RO system was installed to produce boiler feed water and the recovery achieved was around 85%. |

|

|

Sewage Treatment Plant: A new STP was installed which treated 40 kld of water. A significant portion of the gardening needs were catered to by this treated water. |

|

|

Storm water collection treatment and reuse: During FY14, 26,000 kl of storm water was recycled which is an average of 70 kld.. |

|

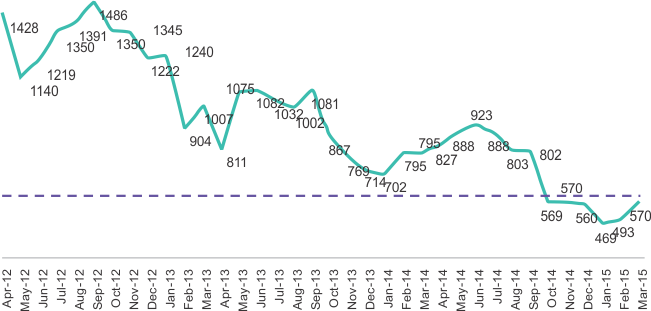

| The graph below represents the trend of reduction in the fresh water consumption year by year from 2012-2015. We are committed to sustain this trend and are exploring reduction possibilities in other areas as well in the next phase. |

| |

| Fresh Water Consumption Trend for the Past 3 Years |

| Freshwater intake Reduction Trend in kld |

|

|

|

These measures successfully

reduced the drawdown of

groundwater by |

| nearly 50%. |

|

|

|

| |

| |

| |

| |