|

|

| |

| |

| ECONOMIC PERFORMANCE |

| SUSTAINABLE SOURCING |

|

|

| Adding Value to Natural Capital |

| Cost of raw materials forms the largest portion of the company's operating expenses. Resource efficiency is hence not just an environmental imperative, it is also a cost necessity. |

Our resource management strategy is mature, well rounded and spans the cycle -

from selecting raw material to procuring it, from careful storage to efficient usage and eventually, responsible disposal. |

| |

| Inventory Management |

| Astute inventory management is the heart of a sustainable operation. It ensures continuity of operations, helps rein in costs and boosts availability of medicines. But all three objectives sometimes demand opposite actions as they are often at cross-purposes. |

| It is thus our constant endeavour, to reduce the number of days of inventory we carry without enhancing the risk to continuity or availability. In FY14, we had 148 days of inventory, whereas in FY15, we curtailed it to 144 inventory days. |

|

|

|

|

| |

|

|

|

|

| |

|

| Responsible Disposal |

| We are accountable for patient safety and recall all expired products. The raw materials, semi-finished goods and finished goods that do not meet the required specifications are incinerated by our external partner, the Ramky Group. To minimise disposal as far as possible, intermediates from our API plants are retested and upon passing stringent tests, are repurposed. |

| Based on our Global Quality Management System, we have instituted an alert mechanism on raw material rejections. Rejections are promptly notified to the vendor and replacements are arranged. Such a vendor is also provided a list of corrective and preventive actions in order to ensure that such incidents don't get repeated in the future. |

| We have also set up a robust process to dispose scrap or discarded assets. In the reporting period, the value generated through sale of regular scrap and discarded assets is as below: |

| ₹ Million |

| |

|

FY13-14 |

|

FY14-15 |

| Revenue generated through sale of regular scrap |

|

55.6 |

|

95 |

| Revenue generated through sale of discarded assets |

|

9.2 |

|

95.1 |

Revenue generated through sale of demolition

generated scrap (buyback) |

|

0 |

|

0.4 |

| Total |

|

64.8 |

|

190.5 |

|

| (All figures are inclusive of taxes) |

|

|

| |

| Rationalising Consumption |

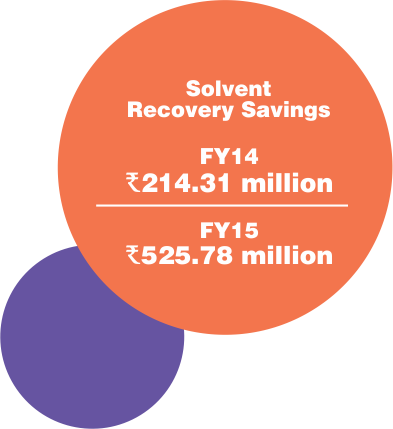

| Not only do we consume with caution, we also curtail resource use via innovative solutions like reducing solvent usage; enhancing its recovery and cutting down on repeated testing. |

| As per legacy procedures, sample test of raw materials was done at multiple points, at API as well as formulations plants. Since 2011, we are focusing on reducing the repeat analysis for raw materials that have demonstrated stable results and have no record of failure. |

| We use a two-pronged approach to reduce testing without compromising on quality: |

|

Reduce duplicate testing at formulations plants for raw materials from API plants |

|

|

Reduce testing parameters for excipients |

|

| |

| This leads to savings in raw material as well as in cost. |

| For details on our solvent management approach and interventions, refer environment section. |

|

| |

| Reduction in Number of Sample Analysis (Injections) |

| |

| RS analysis at formulations manufacturing facility QA/QC labs involves preparation of sample injection, which is loaded in a High Performance Liquid Chromatography (HPLC) system. This injection consists of solvents, chemicals and vials etc. |

|

| Before |

| The SOP involved 2 sample preparations and thus, 2 RS analysis were done for the same set of samples. |

| After |

| One of the technical ideas involved performing only one sample injection for RS analysis. For this, the SOP across Dr. Reddy's was relooked and referenced against the revised Global SOP. Now, only one injection per RS analysis is analysed. |

| Outcome |

| This idea led to various direct and indirect savings. It not only helped in reducing direct resources like solvents, chemicals and vials, but also reduced power consumption, improved column life span and increased HPLC bulb usage. |

| |

| Sustainable Logistics |

| Logistics is a key contributor to our carbon footprint and hence, we are increasingly adopting sustainable alternatives, which cut both carbon and costs. |

| Shifting from air shipment to sea routes is one of our key initiatives. Our teams have successfully improved sea shipments from 24% in FY13 to 40% in FY15, recording an increase of 67%. The target for FY16 is 50% of shipments by sea. |

| Other initiatives undertaken to ensure sustainable logistics include: |

|

Act Replacing wooden pallets with HDPE pallets |

| |

Impact Reduction in wooden pallets helps save trees and elimination of repeated purchase of wooden pallets, due to their lower durability, saves cost. |

|

Act Increase in full truck load shipments for outbound dispatches |

| |

Impact Reduction in the number of trucks and thereby, reduction in carbon emissions and cost of transportation. |

|

Act Introduction of ISO tanks in place of HDPE drums to transport bulk material |

| |

Impact Eliminating usage of HDPE drums by 84 MT. |

|

Act Consolidation of transportation for 'import columns' |

| |

Impact Packing and logistic savings - ₹10 million. |

|

|

|

| |

| Replacement of Wooden Pallets by Slip Sheet |

| |

| |

|

| Before |

| All air shipments were previously loaded on wooden pallets. However, these pallets were expensive, had higher volumetric weight and were susceptible to termite infestation. |

| After |

| Polyethylene Slip Sheets were used as an alternative solution for air shipments. Slip sheets are pallet-sized sheets with great tensile strength and are both, moisture and pest proof. They are also lighter in weight and occupy lesser space within the container. |

| Benefit |

| Compact, low cost, light weight, pest free and more durable than wooden pallets. |

| |

|

|

| |

| |

| |

|

|