|

|

| |

| |

| ECONOMIC PERFORMANCE |

| SUSTAINABLE SOURCING |

|

|

| A Chain is as Strong as its Weakest Link |

| The complex nature of our business, a dynamic business environment and growing stakeholder expectations – make our pursuit of excellence, an evolving endeavour. Thus we are constantly upgrading benchmarks, enhancing processes and refining our systems. |

| But we realise that a chain is only as strong as its weakest link and therefore, with the same zeal, we share the know-how with our various partners. Different engagement and capability building platforms have been designed to embed sustainability in the supply chain and thereby, raise the performance collectively. |

| Over and above enhanced sustainability performance, this collective knowledge boost is enabling standardisation of benchmarks across the chain, higher business efficiency, faster delivery and most important of all, enduring partnerships. |

| Below is a glimpse of our new and ongoing platforms that ensure intensive engagement with the supply chain. |

| |

| Vendor Induction |

| All new vendors undergo a mandatory induction to enhance familiarity with our business processes and culture. |

| The induction training comprises key sustainability parameters like environment, health & safety, ethical trading and human rights. |

|

|

Supplier Training

Sessions |

| A widely adopted knowledge sharing mechanism; during the reporting period, 280 man-hours were invested in conducting supplier training. Training areas included safety, quality, regulatory landscape and sourcing levers. |

| Our SCM professionals were also trained and rated across three competency levels – silver, gold and platinum. |

|

|

| |

|

|

|

|

Troubleshooting Labs

for Vendors |

| Also called the Use Test Lab, its core goal is to help lessen the probability of sudden discrepancies at the time of commercial scale production. |

Performance

Measurement |

| A supplier score card was introduced in the reporting period, to enable supplier rating based on various parameters like price, delivery, quality and D&B Supplier Evaluation Risk Rating. The aim of this one-of-a-kind score card is to rate suppliers more objectively, identify specific interventions for improving their score as well as institute a risk & reward mechanism to encourage high performance. |

| Vendor Risk Assessment |

| We periodically analyse vendor risks pertaining to key aspects such as quality, capacity, finance, environment, health & safety and social responsibility. |

| In the reporting year, we reconducted the D&B Risk Assessment exercise for our top Indian vendors with an aim to anticipate and alleviate risks. |

Global Business

Partners Summit |

| A total of 350 strategic business partners from 5 countries attended the event, where we shared our key business priorities and expectations from vendors on quality, regulatory preparedness, delivery and code of conduct. |

| We also hosted the Annual Business Partners Conference wherein, we recognised high performing vendors. |

|

|

| |

| Vendor Support Lab |

| A dedicated lab to analyse samples as well as extend support in areas of cut-off studies, analytical method validations and method development for few critical molecules. |

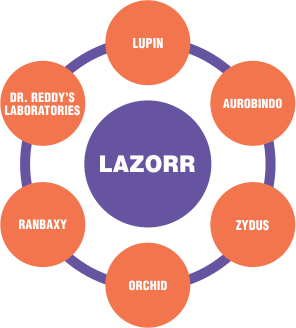

LAZORR: Collaborative

Engagement |

|

| Dr. Reddy's is a member of LAZORR, a-first-in-India alliance of the country's six major pharmaceutical companies, which has been formed to share best practices in core areas including procurement, solvents, energy, safety and water. |

| Dr. Reddy's leads the packaging workstream, sharing insights and possibilities of interventions to optimise packaging. |

|

|

| |

| Safety and Quality |

| Safety and quality gap analysis has been initiated for suppliers to identify shortcomings and prescribe corrective measures. |

| We continue to conduct Quest Meets, a biannual programme to ensure quality compliance among suppliers. |

| |

| Vendor Audits |

| Year-on-year, we conduct vendor audits to ensure robustness of our supply chain. |

| In FY14, 82 vendor audits were conducted wherein, 628 observations were raised including 6 critical observations and 89 major observations. Based on this analysis, 2 vendors were blocked. |

| In FY15, 95 vendor audits were conducted wherein, 627 audit observations were raised including 33 critical observations and 173 major observations. 9 vendors were blocked based on these audits. |

|

|

| |

| |

| |

| |

| |

|

|