|

|

| |

| |

| ENGINEERING EXCELLENCE |

| AUTOMATION |

| Case Studies |

|

|

Automation improves safety and

productivity, provides consistency in

quality, results in shorter turnaround

times and reduces time to market,

so that our medicines are available

wherever and whenever needed. |

| |

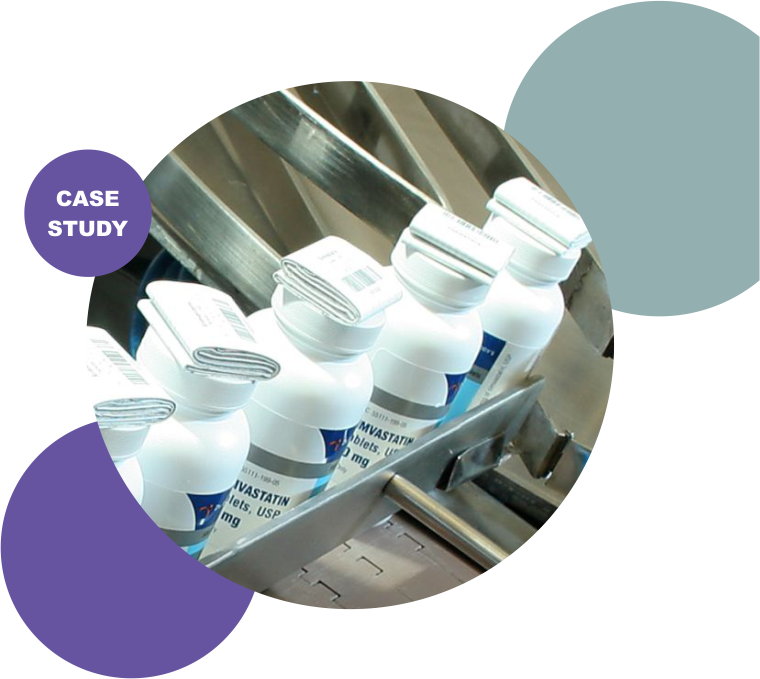

Packing Efficiency

and Quality |

| CHALLENGE |

To maximise efficiency, product safety and

data integrity in the manual bottle and blister

packing lines. |

| |

| ACTION |

We automated the bottle and blister

packing lines to successfully eliminate

manual operations and successfully

completed mechanisation of the

secondary packing lines linked to

finished goods warehouse. The

automation also included an automatic

storage and retrieval system (ASRS),

a first of its kind in the pharma industry. |

|

| |

| OUTCOME |

| THEN |

|

NOW |

| Manual operations |

|

Automated |

| Collation of bottles / blister bundles |

| Erection of inner carton box |

| Transfer of bottles / bundles involved picking up and placing into cartons |

| Closing, taping, labelling & weighing of inner cartons |

| Closing, taping, weighing and transfer of outer cartons to finished goods warehouse |

| Retrieval of finished goods and transfer to bay area for dispatch |

|

|

| Manual operations minimised - 30 to 40% savings in man-hours as compared to past practice |

| Better compliance to cGMP standards |

| Improved product safety and quality |

| Error proof serialisation and aggregation for packing lines |

|

|

| |

| |

| |

|

|