|

Performance Target |

Status |

Progress |

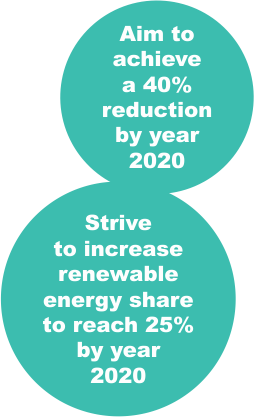

Aim to reduce our specific

consumption of energy by about

5% every year so as to achieve a

40% reduction by year 2020. |

|

Initiated energy conservation measures at

Formulations Plant 3, Formulations Plant 6

and Formulations Plant 8, which will soon be cascaded

to other facilities like API Plant 5 and

API Plant 6. |

Strive to increase the

percentage share of

renewable energy in our total

energy consumption by 2.5%

every year over the next ten

years, such that renewable

energy share reaches 25%

by

year 2020. |

|

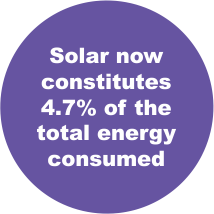

10.3% of total energy is now

from renewable sources,

mainly

due to agriculture waste briquette

fired boilers

in API Plant 1, 4

and

API Plant (SEZ). Solar

energy now

constitutes 4.7% of

the total

energy consumed |

Aim to reduce our specific water consumption of

water by about 5% every year over the next ten years

so as to achieve a 40% reduction by year 2020. |

|

New wastewater recycling facilities were commissioned

at Formulations Plant 1 and 2. Recycling of treated water

resulted in reduction in freshwater consumption |

Strive to become water neutral by year 2020 by

replenishing the water table with an amount of water

equal to what we consume, using means such as

water harvesting. |

|

New rainwater harvesting facilities were

commissioned

at API Plant 5 and API SEZ. These

augment the existing

rainwater harvesting system

at Formulations Plant 3.

Next steps: Studies are being undertaken to explore

further opportunities for rainwater harvesting at other

manufacturing facilities. |

Attempt to reduce our

specific generation of

hazardous waste. |

|

New sludge dewatering system commissioned at

Formulations Plant 3. Segregation of pure salts from

process and their disposal to recyclers at API Plant 5 &

API Plant 6 commenced during this reporting period. |

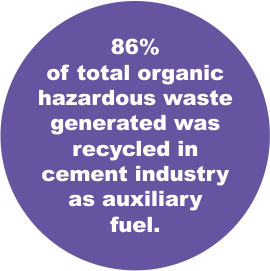

Reduce the quantum of hazardous

waste sent by us to landfill / incineration

by about 5% every year over next

ten years so as to achieve a 40%

reduction by year 2020. |

|

30% of hazardous waste generated was recycled

in

the cement industry as auxiliary fuel. The

Formulations

Business Unit obtained necessary

permits from the

regulators to dispose market

returned goods in

cement plants. |