|

|

| |

| |

| QUALITY |

| QUALITY BY DESIGN |

| Overview |

Introduced first in IPDO in FY13, Quality by Design (QbD) has been

cascaded across all our manufacturing facilities. Today, we have emerged

as the thought leaders in QbD in the Indian pharma space. |

Our aim is to not just stay ahead of the generics manufacturers, but be comparable with the innovators. And we are happy to state that we are

inching closer towards this goal by strategically investing in our people, processes and procedures. |

We have successfully shifted to an electronic lab environment and

provided 685+ scientists across 20 Labs at IPDO with the Electronic Laboratory Notebook (ELN). |

Apart from raising productivity for scientists, peer reviewers, and

supervisors in R&D, e-notebook ensures data integrity leading to

elimination of Level 3 QOIs from DQA / FDA audits. The adoption journey

of the ELN is being closely monitored to ensure speedy

institutionalisation. |

| |

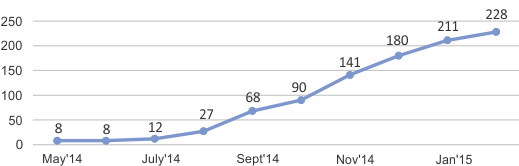

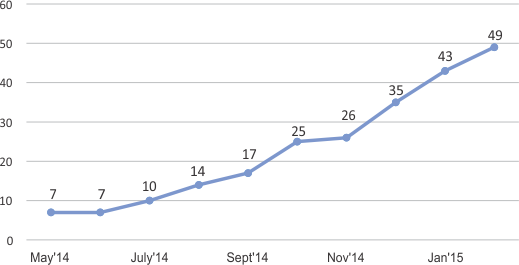

| ELN Adoption Trend (Month-wise) |

| |

| No. of Projects Formulations |

|

| |

| No. of Projects API |

| |

Over and above the ELN technology, we continue to adopt and master advanced tools such as Failure Mode Effect Analysis (FMEA), Process Mapping, Hazard Analysis and Critical Control Points (HACCP), Hazard Operability Analysis (HAZOP), Fault Tree Analysis (FTA) and Cause and

Effect Analysis (CEA). |

But tools are only as effective as the ability of the people who leverage them.

To increase their awareness of the improvement tools and techniques, the focus in the reporting period was on capability building. |

| We signed a contract with ASQ to train our employees in six sigma, a discipline fully aligned with the philosophy of QbD. |

| We are committed to mass six sigma training. 96% of our 1st batch emerged as certified green belts. We also conduct in-house trainings and develop e-learning modules on a regular basis. |

|

| |

| Capability Building Dashboard |

No. of Participants

|

| Six sigma basic course |

150 |

| Lean six sigma green belt |

56 |

| Lean six sigma black belt |

3 |

| Lean phase 1 |

130 |

5S awareness and implementation

programme |

65 |

| MSA and process capability |

45 |

Weekly shop floor trainings for

frontline operators |

388 |

These world-class competencies acquired by individuals will

soon translate into organisational competencies, delivering tangible

business results. |

|

| |

| |

|

|