|

|

| |

| |

| ENGINEERING EXCELLENCE |

PREDICTIVE

MAINTENANCE

|

Equipment downtime doesn't only

mean loss of money, it also implies

unavailability of our medicines. Hence,

predictive maintenance is practiced to

prevent occurrence of failure. |

We use a host of technologies such as

thermography, vibration monitoring, oil

analysis, ultrasonic measurement and

condition-based monitoring in a

proactive manner to improve plant

efficiency, reduce breakdowns, cut

downtime, undertake root cause analysis and reduce energy consumption. |

|

| |

Spotting the Heat

via Thermography |

| The use of thermographs to study heat distribution was initiated to improve electrical safety. The first study was conducted in April 2013 and is now an annual exercise. |

|

45 hotspots identified and corrective actions taken to eliminate them |

|

|

6-monthly thermography study of PCCs & MCCs initiated |

|

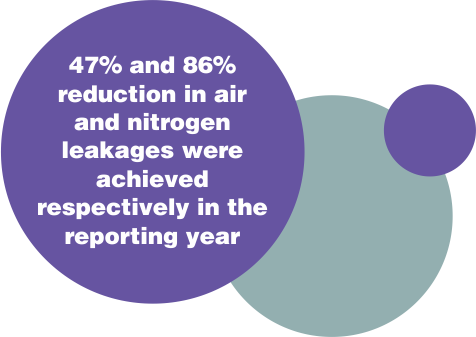

| Detecting Leakages

by Way of Ultrasound |

| Leak detection of compressed gaseous fluids of overhead lines is done using a portable ultrasound diagnostic device - CTRL UL 101. It detects leakages using a piezo electric sensor and converts it into acoustic range, which in turn helps to pinpoint the position of the leak. |

|

|

Condition-based

Monitoring |

In addition to planned scheduled maintenance, condition-based

monitoring helps spot upcoming equipment failure and enables

proactive maintenance. Vibration analysis was carried out for

process equipment like blowers, air handling units, air compressors,

pumps and chillers. |

| ANALYSIS |

|

CORRECTIVE

ACTION |

|

OUTCOME |

Dominant

vibration occurring

at 1X motor rpm |

|

Blower impeller

was found

cracked and was

repaired |

|

Vibration readings

reduced from

12.40 mm/sec to

4.69 mm/sec |

|

| |

| Maintenance through MES |

Dr. Reddy's took up various maintenance projects under MES

including preventive, predictive, breakdown or reliability-centred

maintenance for sustainable performance of the plants. Some of

the key initiatives include harmonisation through SAP and user

verification. Both these initiatives brought in more transparency,

easy tracking of engineering operations and better compliance. |

|

|

| |

| |

| |

| |

|

|