|

|

| |

| |

| ENVIRONMENT PERFORMANCE |

| WATER |

|

|

| Water Conservation Initiatives |

|

| Rainwater Harvesting |

| We have been harvesting rainwater for a few years and the results have been very encouraging. During the reporting year we extended the initiative to cover two more facilities - API Nalgonda Plant and CTO SEZ. |

| We harvested 194,600 kilolitres of rainwater across units - API Hyderabad Plant 4, API Nalgonda Plant, API Srikakulam Plant, CTO SEZ, Formulations Hyderabad Plant 1, 2, 3, Formulations Baddi Plant 1. |

| Rainwater Harvested in

API Plants BU |

| API plants business units consumes 689,000 kilolitres of fresh water per annum. In FY15, 122,000 kl of rainwater was harvested due to which the unit reduced the usage of total fresh water by 17.7%. |

|

| Details of rainwater harvesting at API plants BU are given below: |

| |

| Location |

|

Initiatives |

|

Harvested / Recycled

Quantity kl/annum |

API

Hyderabad

Plant 4 |

|

Two storm water collection tanks of capacities 2 kl each were constructed |

|

1,200 |

| |

5 rainwater collection tanks were provided to collect 150 kl rainwater |

| |

The rainwater was used in cooling towers after passing it through the reverse osmosis system |

API

Nalgonda

Plant |

|

A 3.5 km storm water drainage system was

constructed within the plant |

|

26,000 |

| |

Two storm water collection tanks of capacities

1,000 kl each were constructed |

| |

Two storm water drains were laid to collect

and transfer all the storm water from the site into

the collection tanks. |

| |

The storm water was further treated to make it fit for

consumption in utilities and the reject was sent to

multiple effect evaporators. |

API

Srikakulam

Plant |

|

Three tanks of a total capacity 160 kl were used for

collection of storm water. |

|

14,400 |

| |

The storm water collected was pumped into 800 kl capacity rainwater storage tanks using higher capacity pumps. |

| |

The rainwater was used in cooling towers after passing it through the reverse osmosis system. |

| CTO SEZ |

|

A well thought-out plan was devised for rainwater harvesting |

|

81,000 |

| |

Measures were taken to impound maximum quantity of run-off water generated in the area and backwater coming through the adjacent streams. |

| |

A total of six rainwater harvesting pits, one large irrigation tank spread over 33 acres, an open well and a storage cum percolation pond were constructed |

| |

|

Total |

|

122,600 kl |

|

| |

Rainwater Harvested in the

Formulations Business Unit |

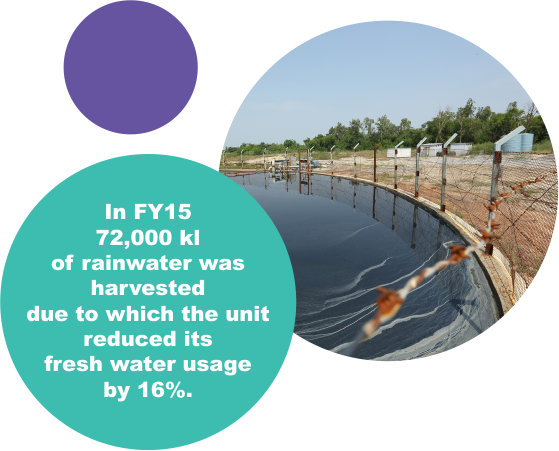

| The Formulations BU consumes 450,000 kl of fresh water per annum. In FY15, 72,000 kl of rainwater was harvested due to which the unit reduced its fresh water usage by 16%. |

| Details of rainwater harvesting in Formulations Business Unit are given below: |

|

| |

| Location |

|

Initiatives |

|

Harvested / Recycled

Quantity kl/annum |

Formulations

Hyderabad

Plant 2 and 3 |

|

Developed infrastructure for collection of total storm water within Bachupally campus |

|

1,200 |

| |

Landscaping of surrounding area of the pond, total storm water connectivity within area |

| |

Floating aerators installed in both rainwater harvesting ponds and rainwater storage ponds to improve the water quality |

| |

From Contour diagrams, studied existing rainwater harvesting pits and

re-routed rainwater to rainwater ponds |

| |

|

Total |

|

60,000 kl |

|

| |

| Technical feasibility of rainwater harvesting at Formulations Vizag SEZ Plant, FTO 9, Baddi Plant 2 & FTO SEZ sites is on

the anvil |

| Budhera (Zaheerabad) - Technical feasibility is being carried out |

| Technical feasibility & possibility of implementing rainwater harvesting in hilly areas of Telangana and Andhra Pradesh is being evaluated |

|

|

| |

| |

| |

|

|